Inquiry

Form loading...

-

E-mail

-

Whatsapp

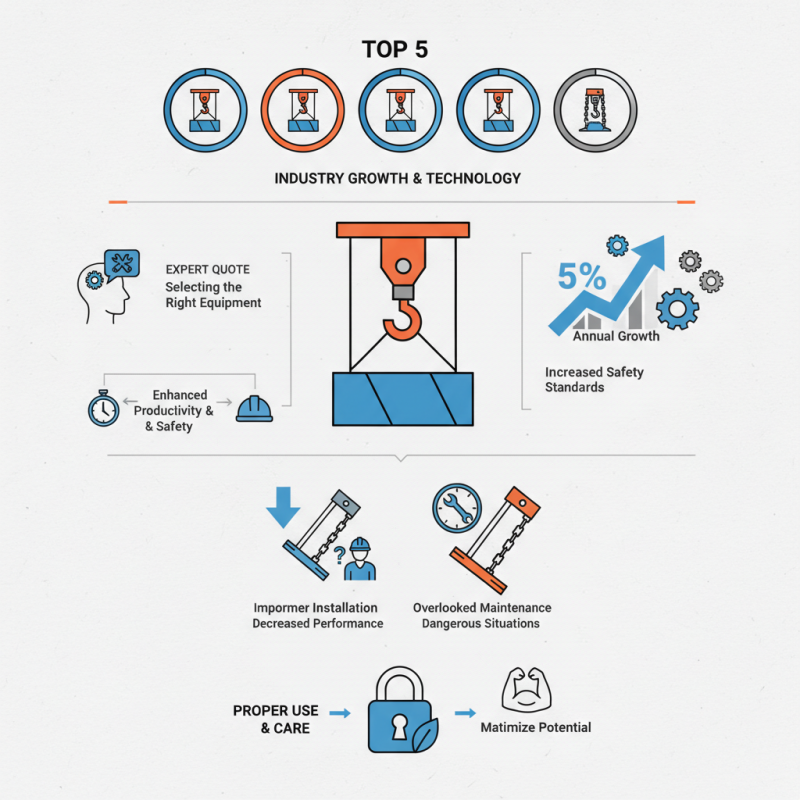

In today’s fast-paced industrial environment, efficient lifting solutions are essential. The Chain Block Crane is a pivotal tool that meets this demand effectively. According to the "2022 Global Chain Block Crane Market Report," the industry has seen a consistent growth rate of 5% annually. This growth is attributed to advancements in technology and increasing safety standards in lifting operations.

Expert John Smith, a leading authority in hoisting technology, emphasizes the significance of selecting the right equipment. He states, “Choosing the right Chain Block Crane can drastically enhance productivity and safety on-site.” With diverse models available, it can be overwhelming for businesses to choose. However, the right choice not only boosts efficiency but also minimizes risk.

Despite advancements, challenges remain. Some users report that improper installation can lead to decreased performance. Regular maintenance is often overlooked, which can result in dangerous situations. The key is not just to invest in a Chain Block Crane but to ensure proper use and care to maximize its potential.

Chain block cranes are pivotal in various industrial sectors. They facilitate lifting heavy loads efficiently. These tools are widely used in construction, warehouses, and shipyards. Their design allows for ease of use in tight spaces. Operators often find them indispensable for heavy lifting tasks.

In practice, operators must be mindful of safe lifting practices. Regular inspections are essential to maintain reliability. Overloading these cranes can lead to accidents. Proper training for handlers is crucial. Users should also pay attention to the specific weight limits. Understanding each crane's capabilities can prevent misuse.

Applications extend beyond traditional lifting. They are used in installations and maintenance tasks. However, not every chain block crane fits every situation. Assessing the environment and load type is vital. Each task presents unique challenges. A well-considered approach often leads to improved efficiency.

| Model | Lifting Capacity (ton) | Lift Height (m) | Weight (kg) | Application |

|---|---|---|---|---|

| Model A | 2 | 3 | 8 | Construction |

| Model B | 3 | 5 | 10 | Manufacturing |

| Model C | 5 | 4 | 12 | Warehousing |

| Model D | 10 | 6 | 20 | Heavy Equipment |

| Model E | 15 | 8 | 25 | Mining |

When selecting a chain block crane, key features shape your decision. Load capacity is crucial. Always assess the weight you need to lift. Not all cranes can handle heavy loads. Misjudging can lead to accidents. The lifting height matters, too. Ensure the crane can reach your required elevation.

Durability is another factor. Look for sturdy materials that withstand wear and tear. Weather resistance is vital for outdoor use. You don't want a crane that rusts quickly. Ease of use also plays a role. A user-friendly design ensures safety and efficiency. Test the controls for smooth operation.

Safety features should not be overlooked. Emergency stop buttons, limit switches, and overload protection are essential. These can prevent serious accidents. Maintenance needs also come into play. A crane that requires frequent repairs can become a headache. Reflect on these details. Making the right choice can significantly impact your operations.

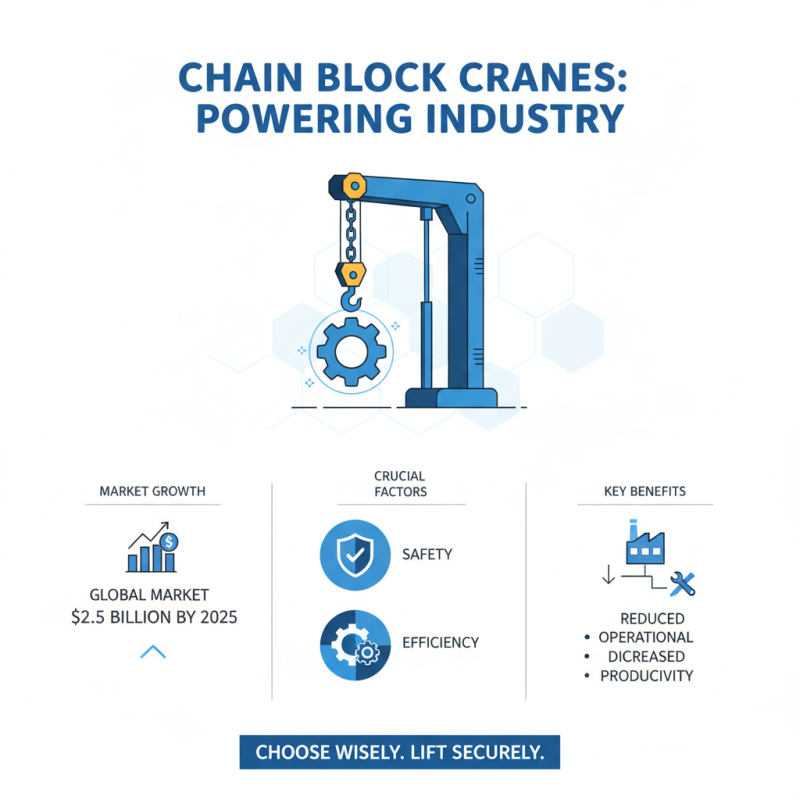

When it comes to heavy lifting, choosing the right chain block crane is crucial. The global market for chain block cranes is projected to reach $2.5 billion by 2025, driven by increasing industrial activity. Companies must look for cranes that ensure safety and efficiency. A well-designed crane can significantly reduce operational downtime.

Consider the lifting capacity. Most standard chain block cranes range from 1 ton to 20 tons. Users often overlook the importance of load limits. Choosing the wrong capacity can result in equipment failure. Additionally, crane design affects its usability. A compact design can save space without sacrificing performance.

Maintenance is another critical factor. Regular inspections can prevent accidents. Industry reports indicate that improper maintenance leads to 30% of crane-related accidents. Investing in robust maintenance routines can mitigate these risks. However, many facilities struggle to adhere to these practices consistently. This gap highlights the need for workers to prioritize safety over convenience.

When considering the best chain block cranes, efficiency and performance are vital. Choosing the right model directly impacts your operations. Here’s what to consider.

The lifting capacity is key. Some models offer higher weight limits, while others excel in portability. A lightweight crane is easier to handle, but might not lift as much. Make sure to match the weight needs with the crane's capabilities. Efficiency also depends on the speed of lifting. Some cranes operate quickly, while others are slower but more controlled.

**Tips:** Always check the energy consumption. Efficient models save on power bills. The gear ratio is also important. A higher gear ratio can lift heavier loads with less force.

Look for features that enhance usability. Some cranes have safety mechanisms that prevent overloading. Others may include a manual override. These can be lifesavers in emergencies. Yet, not all features are necessary for every operation. Reflect on daily tasks to select the best fit.

**Tips:** Consider user reviews and feedback. They often highlight real-world performance issues. Small problems in design can affect overall efficiency and safety. Balancing performance and practicality takes time. Evaluate options carefully before making a decision.

Maintaining chain block cranes is essential for longevity and safety. Regular inspections prevent unexpected failures. Check for wear in lifts. Look for loose components and unusual noises. These signs can indicate potential issues.

Lubrication is crucial. Apply appropriate lubricant to moving parts. However, over-lubrication can attract dust and grime. Balance is key. Keeping the crane clean adds to its lifespan. Dust and dirt can cause internal wear.

Never neglect the cables and chains. Inspect for fraying or rust. Replace worn parts immediately. Adjustments may be necessary as usage patterns change. Regular maintenance schedules help catch problems early. Ultimately, these practices can extend the life of machines significantly.